Air Conditioning System

Air Conditioning System

PP melt blown filter element uses polypropylene (PP) thermal...

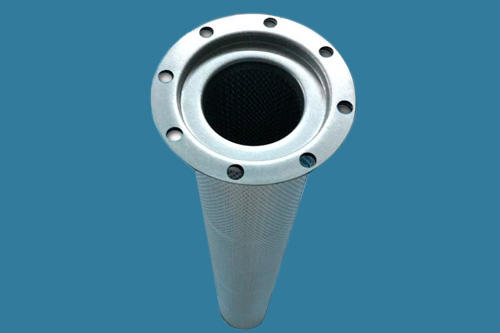

D.King high quality and performance pleated replacement flange-top style cylindrical cartridges offer a convenient alternative when replacement of the original cartridge is necessary. These flange-top style cylindrical cartridges are direct replacements and are exacting application fit and exceed oem performance. With galvanized end caps our cartridges our manufactured with optional Cellulose, 80/20 Polyester/Cellulose or Synthetic Media.

Flange

Square, rectangular or round flange top cartridge filters. Galvanized or stainless steel construction. Manufactured to fit a wide variety of OEM designs. Cartridges can be manufactured with wet laid, spun bond or needled felt media, in full continuous lengths up to 60". A wide assortment of gaskets. Operating temperatures form ambient to 400°F.

Pleated

These cartridge filters are used for powder paint collection and other process related ventilation systems. Heavy-duty construction makes for an ideal primary filter. Variety of custom media also provides excellent filtration and capture of fine particulate. Combination synthetic and cellulose (QX) media is most commonly found in powder paint spray booths. To facilitate improved powder reclaim, spun bond polyester media (SB) is recommended.

Cost-saving, high-quality alternative for premium priced brand-name cartridge filters for Nordson, Gema Volstatic, Torit®, Farr, Tenkay®, Randsburg, Wagner and many other paint booth systems.

standard structure:

|

Top cap |

Galvanized steel |

|

Snap ring |

Needle felt |

|

Inner mesh |

Galvanized steel / stainless steel |

|

Outside straps (optional) |

High temp.Ryton |

|

Bottom cap |

Galvanized steel / stainless steel |

|

Potting compound |

High temperature polyurethane |

|

Filter media |

100% filament spinning spun bonded polyester |

|

Continuous operating temp. |

130 ℃ |

|

Media Options: |

||

|

CB |

|

Carbon and synthetic fibers blended with cellulose to create a conductive surface. Recommended for use in applications where dissipation of static charges is required. |

|

CX |

|

Proprietary grade of 100% cellulose fibers. Excellent efficiency, recommended for a wide variety of applications. |

|

FR |

|

Contains a fire retardant chemical treatment that inhibits combustion of media. Recommended for use in applications where sparks or hot dust particles cause the potential for fire. |

|

KV |

|

Kevlar® media. Contains blend of Kevlar® and Nomex® fibers to handle elevated temperatures. Media can be operated continuously at temperatures of up to 350°F. |

|

AR |

|

Aramid fibers for 375°F have dimensional stability and superior dust release properties, which make it the ideal selection for many high temperature, non-chemical applications. When combined with the efficiency of a PTFE membrane, it does an excellent job for those extremely fine particle filtration applications. |

|

PE |

|

Polyester needled felt media. Good abrasion resistance. Singed surface treatment for improved dust release. Capable of operating at temperatures up to 250°F. |

|

PE-TX |

|

Polyester needled felt media with PTFE impregnated surface treatment. Promotes improved release of sticky or tacky agglomerating dusts. |

|

QX |

|

A blend of premium synthetic and cellulose fibers for heavy-duty applications. Exhibits excellent dust filtration qualities. Utilizes proprietary resin system for improved structural strength and durability. |

|

SB |

|

Spun bond polyester media. Self-supported structure makes it ideal for pleated surface. Features a hard-impact resistance surface with very good filtration properties. Available in a variety of surface treatments and finishes. |

|

SX |

|

Blend of synthetic and glass fibers. Superior filtration media with excellent flow capacity and dust release. Capable of operating in continuous temperatures up to 275°F. |

|

Tech-Felt |

|

Polyester needled felt with expanded PTFE membrane. Maximum efficiency capability with superior release characteristics. Capable of operating in continuous temperatures up to 275°F |

|

MTR Model |

Cover Material |

Tube Sheet H.D (mm) |

Top Cover O.D (mm) |

Bottom Cover O.D (mm) |

Filtration Surface/1m (square meter) |

Filtration Surface/2m (square meter) |

|

KLX-127 |

Galvanized metal |

Φ127 |

φ146 |

φ114 |

1.1 |

2.3 |

|

KLX-133 |

Galvanized metal |

Φ133 |

φ152 |

φ121 |

1.5 |

3.0 |

|

KLX-159 |

Galvanized metal |

Φ159 |

φ178 |

φ144 |

2.1 |

4.1 |

|

KLX-162 |

Galvanized metal |

Φ162 |

φ178 |

φ146 |

2.3 |

4.6 |

Please fill in the form below and one of our teams will be in touch with you.