Air Conditioning System

Air Conditioning System

PP melt blown filter element uses polypropylene (PP) thermal...

Air intake filters protect the compressor from any dust and dirt which it might suck in. The intake-air filter is the most important filter on your compressor! Dust is the number 1 enemy of your compressor: it will cause wear to the compressor element, valves and other parts. It will save also your compressors oil, oil separator, oil filters and all other moving parts.

The compressor air filters need to be cleaned and/or replaced regularly. Normally replacing the air intake filter is part the standard service routine. In very dusty / dirty environments it’s better to clean them once in a while (blow the dust off with compressed air).

Save money! An air compressor with dirty inlet filter(s) will reduce the output capacity. You will pay more money through your higher energy bill than the cost of a new filter! And need I say it? Never run your compressor without the air filter connected!

Also, if your compressor is installed in a very dusty or dirty environment (metal workshop with oily air, wood workshop with a lot of dust, sand-blasting workshop, etc) … do yourself and your compressor a favor: put the compressor in its own room with fresh air, or install ducting to supply the compressor with fresh air.

This will save you a lot of maintenance issues (especially clogged air filters and coolers and over-heating compressors as a result of that)

Principle

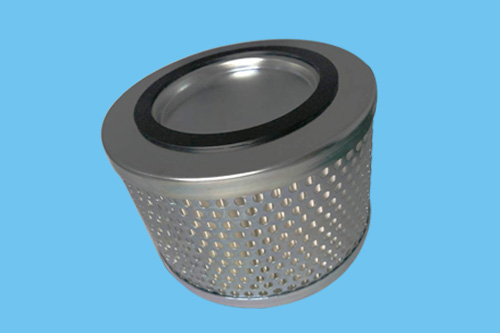

The oil and gas separation filter is the key component to determine the air quality of the injection screw compressor. With proper installation and good maintenance, the quality of compressed air and the service life of the filter cartridge can be ensured.

Out of the nose compression screw compressor of air with different sizes of oil droplets, lard drops through the oil and gas separation tank is easy to separation, while small droplets (slurry) must be micron grade by the oil and gas separation filter glass fiber filter material to filter. The correct selection of fiberglass diameter and thickness is an important factor to ensure the filtering effect. After the oil mist intercepts, diffuses and polymerizes, the small oil droplets quickly coalesce into a large oil droplet, through the filter layer under the action of pneumatic and gravity, and settle at the bottom of the filter core. The oil is imported through the back pipe of the bottom concave of the filter core and continuously returns to the lubrication system, which makes the compressor discharge more pure and high quality compressed air.

Please fill in the form below and one of our teams will be in touch with you.